© Patrick White, Imagine Greater 2021 graphics art, website creation, video all aspects.

All Fluid Film Handling Components | Spares | Fast

Delivery | Service | Consultation | Competitive Prices.

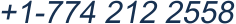

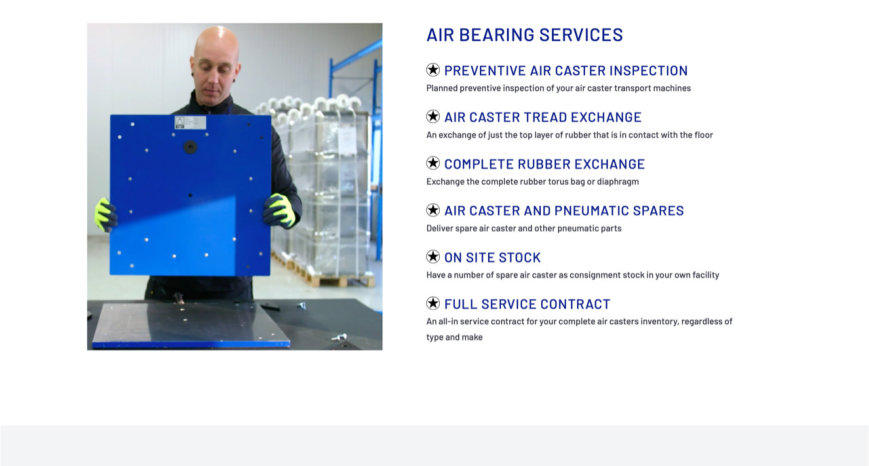

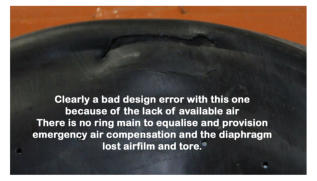

REPLACEMENT AIR CASTERS OF ALL OEM MANUFACTURED TYPES Durable, high grade materials are the standard at Hover Transport Systems BV in the Netherlands where our precision manufacturing facility is situated, a location which enables us to create high quality products on a constant level. The cost-effective production process that we invented enables us to produce air casters that are compatible with the air casters of other manufacturers going back to the BHC Hoverpad the origional invention by Sir Christopher Cockrill. It is important to note that our unique design enables us to replace the wearing parts. No longer do you have to carry the costs of replacing the entire unit! It saves up to 50% in both purchasing and transport costs because the replacement diaphragm or Torus element can be folded and sent by mail as a repair kit that soon will be as easy to buy as a bar of soap.

All Fluid Film Handling Components | Spares | Fast

Delivery | Service | Consultation | Competitive Prices.

NEOPRENE AND POLYURETHANE AIR CASTERS

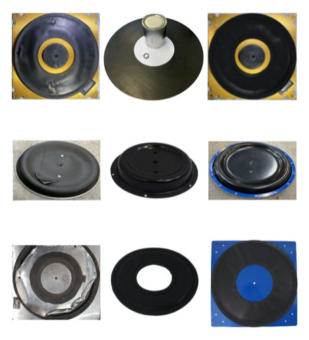

The extrodinary becomes ordinary as one man moves five tons of machinery with his bare hands. One pound of push moves one thousand pounds of load. Since 1990 I have done it so many times yet there is still an euphoria that comes from this simplification of a task that usually requires a massive effort. Air casters in operation look similar to the movement of a hovercraft across a surface without a wild storm of air a graceful, smooth and easy action over the floor using a simple technology that distributes the load in such a way that there is a far lower point load on the floor and no damage from the frictionless movement, almost like floating on water. That is me in the picture to the right moving a five ton section of a paper mill and that is exactly what we make at Hover Transport Systems BV. Hover transport Systems produce both the neoprene and the polyurethane types of elements that are used in air casters and the GM style air bearing. The factory is the sole creator and product developer which enables them to produce replacement air casters that are 100% compatible with all OEM manufacturers such as Solving, Aerogo, Kohan Kogyo, Delu, and Aerofilm Systems. Neoprene and polyurethane air casters have different advantages listed below:Pro’s and Cons

1. Taurus bag Neoprene Air Casters have a higher lift, than the polyurethane Air Bearing GM type. 2. Objects are lifted higher off the floor but the cost is more air. 3. The Taurus bag type is especially handy if you want to move a range of different objects. 4. These air casters also have a large load capacity: they have twice the capacity of the polyurethane diaphragm type of Air Bearing. 5. Polyurethane Diaphragm Air Bearings consume less air compared to the neoprene types. 6. The polyurethane material is more durable. APPLICATION OF AIR CASTER TECHNOLOGY Moving heavy loads can be simplified in so many more applications now that we have set free the availability of a product once sold only with equipment or as a spare part for existing OEM equipment. Our range of products will enable smaller enterprises, engineering shops and new products to be set free on the market. A fast, simple, and above all safe transportation of your equipment. What is best for you: At AerGlide USA and Hover Transport Systems BV we are not tied to any single Fluid Film technology because we make them all and we are competently able to consult and provide the best solutions for your specific need and find the ultimate outcome. Safe: Loads are lifted from underneath, and no harmful exhaust gasses are produced during motion across the floor. Fast: It only takes a few minutes to install the air caster system, which allows the oporator to position the load to be moved accurately. Simple: You just need compressed air and a suitable floor.

NO HANDOVER OR TRAINING BY THE SELLER

THIS SHOULD NEVER HAPPEN!

WHAT WILL BE THE THE FATE OF THIS EXPENSIVE

EQUIPMENT ? DUMP ? STORED AWAY? EBAY?

ASK FOR PATRICK WHITE

HE HAS BEEN PUSHING AND SHOVING HEAVY LOADS ON AIR

FOR 30 YEARS

We provide consultation and training

cONSULTATION AND ADVISE

aERGLIDE AND hOVER tRANSPORT sYSTEMS

PROVIDING INNOVATIVE AIR CASTER REPLACEMENT

SOLUTIONS THROUGH DIRECT REPLACEMENT,

hybridizeD SYSTEMS, RECONDITIONING SERVICE

AND REMANUFACTURED AIR CASTERS